Our Focuses|Environmental Sustainability|Water Management

Water Management

Winbond adheres to the vision of "Being a hidden champion in providing sustainable semiconductors to enrich human life." fulfilling

the responsibility of green manufacturing, reducing the impact and influence of corporate operations on the environment, aiming to

fulfill social responsibility and sustainable management.

All of Winbond's production facilities have passed the ISO 46001 Water Efficiency Management System certification. This ensures the effective management of water supply-related risks, the measurement and monitoring of water usage, the improvement of overall performance, and the reduction of water consumption to minimize environmental impact.

To understand the water resource risk situation, Winbond uses the World Resources Institute (WRI) water

risk assessment tool, adopting the "Aqueduct Water Risk Atlas" through the AQUEDUCT website to analyze

the distribution of water resources in Taiwan, understanding that all Taiwan operation sites are located in low-risk areas for water resource pressure.

See Winbond Water Efficiency Policy、Certification and Verification

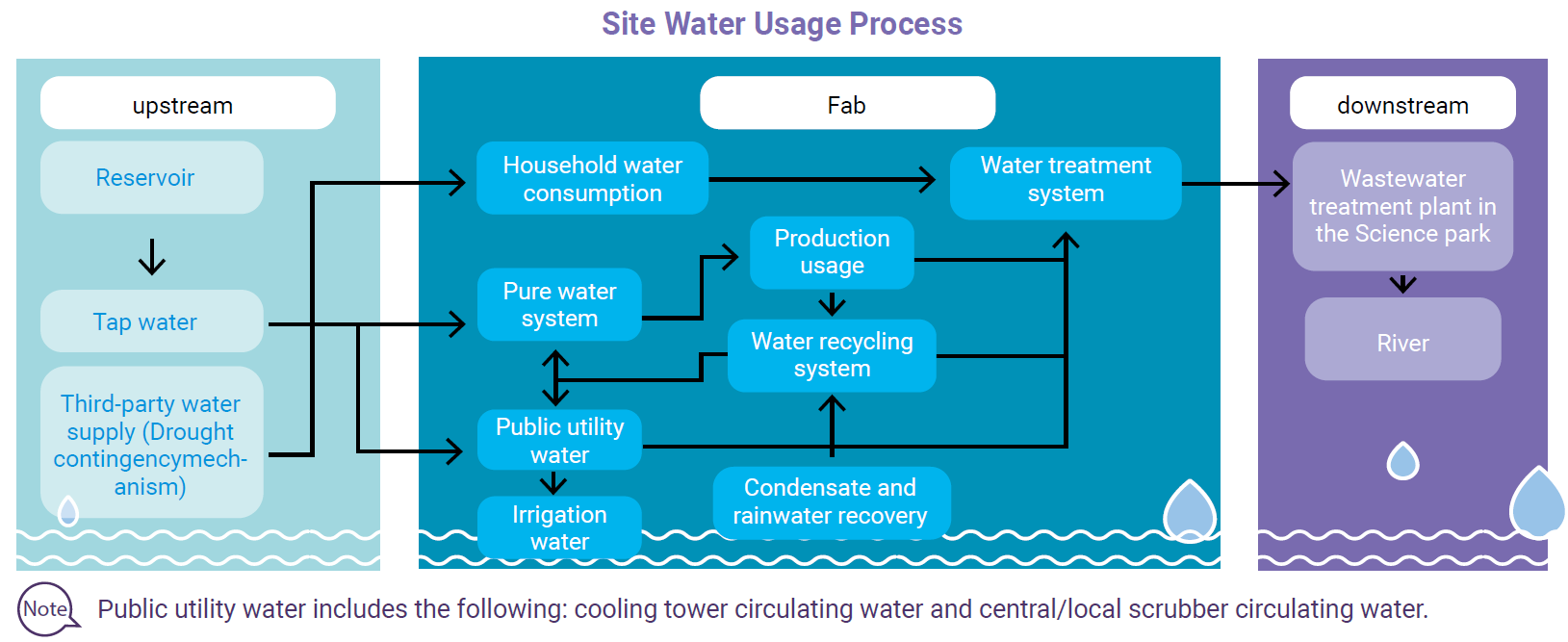

Water Recycling

In response to the advancement of semiconductor process technology, the consumption of water resources in the manufacturing process has gradually increased, making the reasonable management of water resources an urgent issue.Winbond’s main source of water is tap water supplied by the Taiwan Water Corporation, sourced from the Liyutan, Deji and A Gong Dian Reservoir. A small portion of the water comes from rainwater and air conditioning condensate.

Site Water Usage Process

Winbond continued to increase the reuse rate of recycled water, implementing 10 new water-saving measures in 2024, resulting in an increase of approximately 155,000 cubic meters of water saved. In 2024, the overall plant recycled approximately 81.9% of its water and 89.3% of its process water (meeting the science park’s commitment under the environmental impact assessment to recycle more than 77% of all water used, and more than 85% of all process water used).

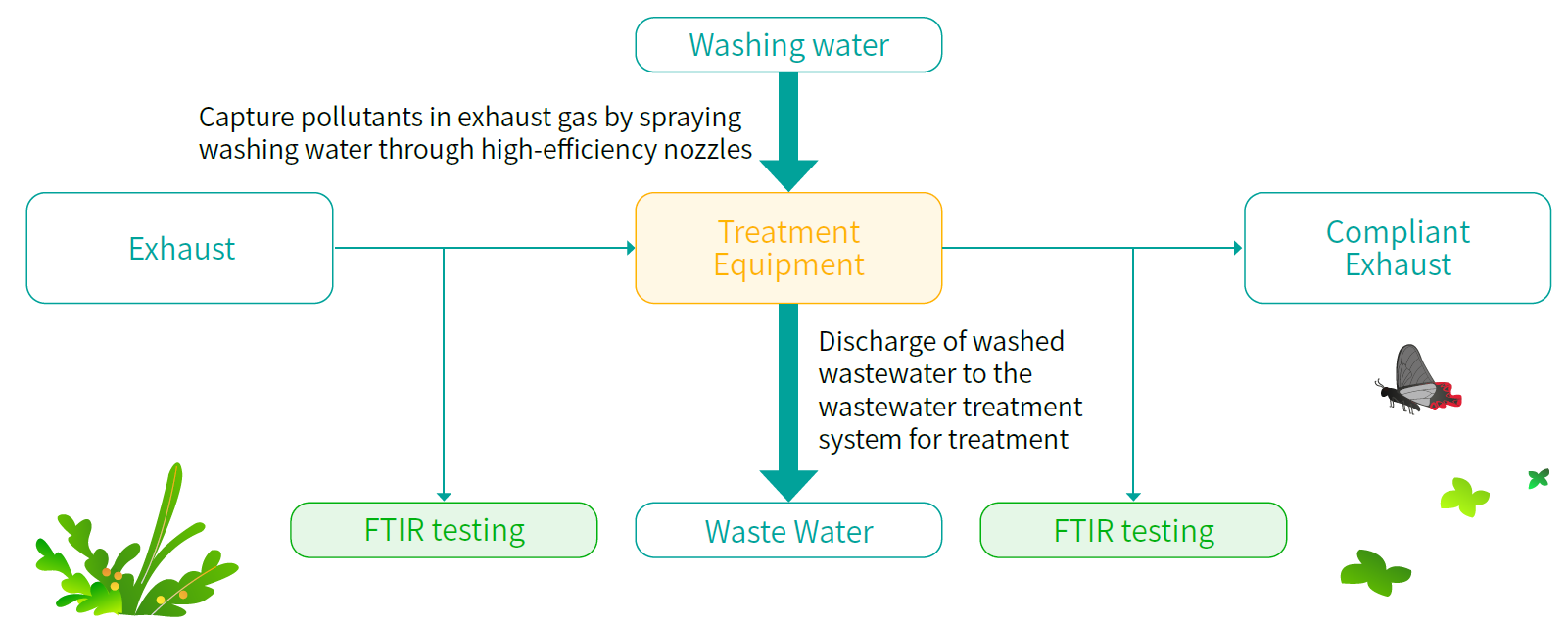

CASE:Water-saving in exhaust gas treatment equipment

Winbond is committed to achieving water conservation through various measures. Collaborating with exhaust gas treatment equipment manufacturers, Winbond gradually reduces the washing water flow for exhaust gas treatment equipment with lower loads, while simultaneously conducting emission concentration tests to ensure that the test results meet the requirements. This can save approximately 22,776 tons of water annually. Under the condition of meeting emission requirements, it effectively reduces the use of water resources and wastewater discharge.

Winbond water resources goals and water conservation measures

2024, Metric for measuring water intensity per product unit, Winbond averaged 147 liters of water usage to produce one 12-inch wafer photomask layer.

| Indicators and Targets | 2024 Targets | 2024 Achievements |

|---|---|---|

| Fab Water Recycling Rate (%) | ≧80% | 82% |

Note: Fab Water recovery rate: The statistical scope of the data is Winbond Taiwan factory.

— 2024 Water Saving Measures (Unit: megaliters /year) —

| Item | Conservation Projec | Description | Water Savings |

|---|---|---|---|

| 1 | Water-saving in process equipment | Adjust parameters of process equipment to achieve water reduction | 71.2 |

| Adjust parameters of exhaust gas treatment equipment to achieve water reduction | |||

| 2 | Water-saving in facility equipment | Reduce tap water usage by using recycled water in cooling towers | 83.3 |

| Extend the operating hours of pure water system units to achieve water reduction |

Note: The scope of water conservation measures statistics is the Winbond (Taiwan) fab.

Winbond Group's Water Resources Management

— Water Withdrawal, discharge and total net fresh water consumption(Unit: megaliters)—

Water Resources Types | 2021 | 2022 | 2023 | 2024 | ||||

|---|---|---|---|---|---|---|---|---|

Winbond (Taiwan) | Subsidiaries | Winbond (Taiwan) | Subsidiaries | Winbond (Taiwan) | Subsidiaries | Winbond (Taiwan) | Subsidiaries | |

| Total Water Withdrawal | 3,293 | 391 | 4,131 | 410 | 4,356 | 396 | 4,564 | 3,931 |

Water discharge | 2,318 | 319 | 3,172 | 312 | 2,924 | 317 | 3,204

| 3,591 |

Total net fresh water consumption | 975 | 72 | 959 | 98 | 1,432 | 79 | 1,360 | 340 |

- Consolidated financial statements Subsidiaries statistical data (2021-2023 Subsidiaries scope only includes Nuvoton (Taiwan)).

- Winbond Group's 2024 target for Water Consumption per unit revenue was set at 24.51 m³/NT$ million, and the actual value achieved was 20.83 m³/NT$ million, meeting the target requirement.

— Ultra-pure water usage(Unit: cubic meters )—

Water Resources Types | 2021 | 2022 | 2023 | 2024 | ||||

|---|---|---|---|---|---|---|---|---|

Winbond (Taiwan) | Subsidiaries | Winbond (Taiwan) | Subsidiaries | Winbond (Taiwan) | Subsidiaries | Winbond (Taiwan) | Subsidiaries | |

| Ultra-pure water | 7,329,565 | 498,589 | 6,753,960 | 485,106 | 8,416,193 | 451,900 | 8,590,883 | 1,585,360 |

- Consolidated financial statements Subsidiaries statistical data (2021-2023 Subsidiaries scope only includes Nuvoton (Taiwan)).

- Winbond Group's 2024 target for ultra-pure water consumption per unit revenue was set at 128.91 m³/NT$ million, and the actual value achieved was 124.69 m³/NT$ million, meeting the target requirement.

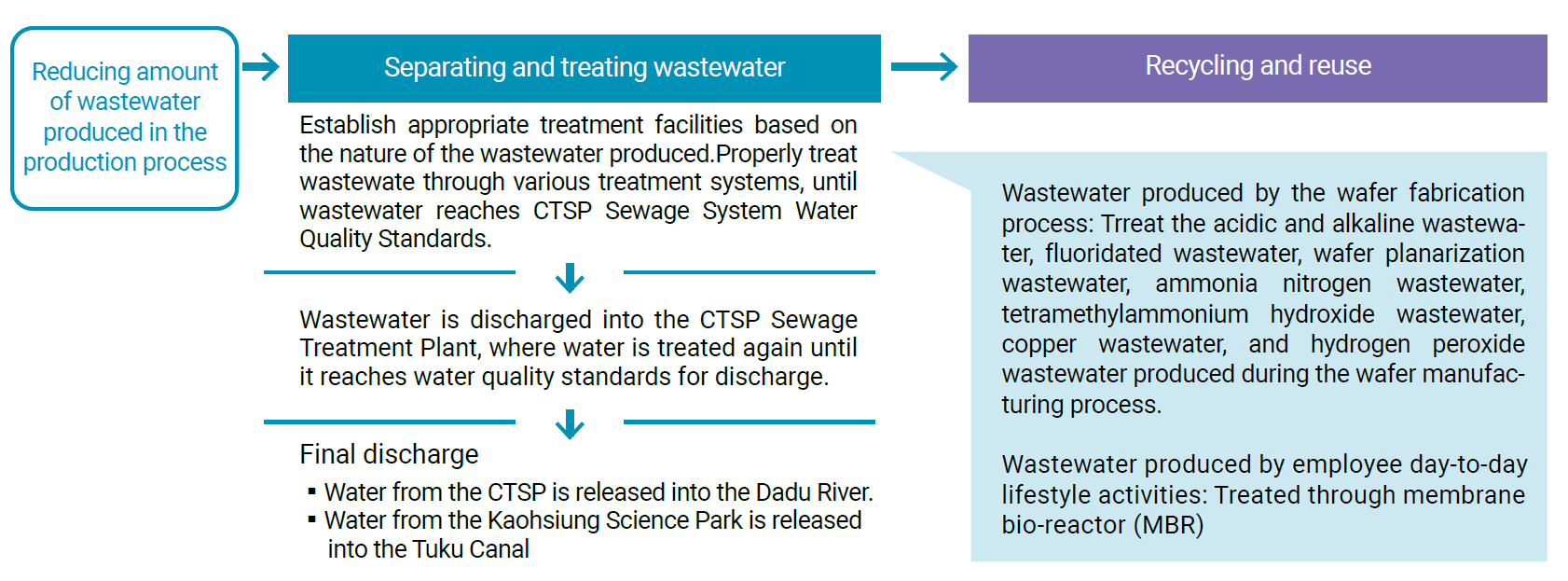

Wastewater Management

Winbond’s wastewater treatment facilities are designed to collect up to 20 types of waste liquids through separate pipelines standardizing wastewater quality. Each wastewater type is then treated through 11 distinct wastewater treatment facilities. Operating and discharge permits are applied for pursuant to the Water Pollution Control Act and the Soil and Groundwater Pollution Remediation Act.

Testing is conducted by a laboratory accredited by the Environmental Analysis Laboratory twice a year to confirm that the discharge water quality satisfies Science Park Bureau influent standards. Additionally, in order to reduce the environmental burden of the wastewater treatment facility, and to reduce the use of chemical products, Winbond also collect and treat waste liquids from the washing towers, cooling towers, process cooling water, and recycled soft water from production processes, reusing this treated waste liquid in secondary water applications throughout the site Apart from these measures, Winbond has continued to promote improvements to our water pollution prevention facilities, reduced our pollutant biochemical oxygen demand (BOD), chemical oxygen demand (COD), and the amount of suspended solids (SS) and sludge.

In 2024, the test data for BOD, COD, and SS were all better than the water quality standards set by the Science Park Administration Bureau.

Winbond's 3 major principles for plant wastewater treatment