Our Focuses|Sustainable Supply Chain|Sustainable Supply Chain Communication

Supply Chain Sustainability Engagement and Assistance, Support

To effectively advance supply chain management towards sustainability, Winbond integrates technical and quality-oriented approaches with innovative thinking and management models in its existing supplier collaboration efforts. In addition to regular environmental, safety, and health (ESH) training for suppliers/contractors and outsourcers conferences, new initiatives have been added to the agenda. For example, Supplier ESG Learning Hub, Internal ESG Education Training for Colleagues, Sustainable Supply Chain Upgrade+ Forum, and Advanced Packaging Technology Forum.

Management Process for Sustainability Collaboration Activities

-議和活動管理流程.png)

Suppliers Empowerment Initiatives

Since the establishment of the Sustainable Supply Chain team in 2022, Winbond has been actively seeking opportunities for suppliers to join the sustainability ranks. In 2024, we carried out a total of four sustainability training projects for supplier sustainability management, including "Winbond Supplier Energy Conservation and Carbon Reduction Diagnostic Counseling", "Carbon Data Electronic Data Interchange - PACT Advanced Demonstration", "Supply Chain Sustainable Logistics and Lowcarbon Transportation", "Reinventing the New Project - Recycling of Waste PVC Gloves", etc., and as of 2024, a total of 62 suppliers had accepted Winbond's sustainability agreement and training. In the future, Winbond will continue to uphold the principle of shared prosperity within the supply chain by partnering with suppliers who share our commitment to sustainability, expecting these projects to serve as powerful industry demonstrations that influence more suppliers to join us in a virtuous cycle.

| Supplier Capacity Building Program | Number of suppliers involved | |

|---|---|---|

2022 | Co-Sustainability project – ESG perspective exchange and co-learning | 32 |

2023 | Winbond Electronics' low-carbon transformation cooperation project for sustainable supply chain | 13 |

2024 | Supplier energy conservation and carbon reduction diagnostic counseling | 2 |

Electronic data exchange of carbon data - PACT preliminary evidence | 9 | |

Supply chain sustainable logistics and low-carbon transportation | 2 | |

Reinventing the new life project - scrap PVC gloves for recycling | 4 | |

| Total number of suppliers in capacity building programs | 62 | |

| % of unique significant suppliers in capacity building programs | 95% | |

Note : % of unique significant suppliers in capacity building programs = Total number of suppliers in capacity building programs / number of significant suppliers in 2024

Regular ESH Training for Suppliers/Contractors

To effectively maintain safety in the workplace at Winbond and enhance suppliers' awareness of occupational safety during work, Winbond annually provides relevant training for supplier employees engaged in on-site work or stationed at the facilities. This training covers workplace equality and epidemic prevention. Given the specific environment of semiconductor work, Winbond conducts comprehensive hazard notification and special operation education training for incoming supplier employees each year to ensure occupational safety and health. In 2024, a total of 3,362 hours of training were conducted, including sessions at the Zhubei Building, the CTSP and the Kaohsiung fabs.

| Topic | Content | Number of people | Total training hours (people * hours) | Factory |

|---|---|---|---|---|

| Equality in workplace | Training and advocacy on workplace bullying, abuse, harassment, etc. | 28 | 13 | CTSP fab |

| 36 | Kaohsiung | |||

| 9 | Zhubei | |||

| Occupational safety and health | Hazard Communication and Special Operations Training | 1,547 | 3,320 | CTSP fab |

| 1,490 | Kaohsiung | |||

| 283 | Zhubei |

Deep Engagement – Suppliers ESG Co-learning workshop

Since launching the Sustainable Supply Chain initiative, Winbond has expanded collaborative learning workshops to cover environmental resource reduction, climate change measures, greenhouse gas and carbon management, human rights and labor protection, and corporate governance and ethics. By 2024, 33 companies participated, with 2,078 participants and 4,169 personhours of learning.

This year, for the first time, the workshops included entities that are both suppliers and customers, fostering diverse dialogues. Winbond's innovative sustainable learning mechanism keeps up with ESG trends in the semiconductor industry and benefits from the sharing of best practices by benchmark suppliers. This allows Winbond to learn diversified ESG practices and acquire new ESG knowledge.

Internally, these workshops provide the latest industry information to colleagues, aiding in the planning and execution of Winbond's supply chain sustainability efforts. Externally, the workshops are becoming a platform for supply chain members to disclose their sustainability beliefs and practices.

Looking ahead, Winbond aims to use this collaborative learning model to stimulate research and development in low-carbon processes and green products among suppliers, enhancing the international competitiveness of Taiwan's semiconductor supply chain.

Winbond's Supplier ESG Co-learning Process

-ESG共學工作歷程.png)

Winbond's Supplier ESG Co-learning Performance

-ESG共學工作績效2025.png)

Co-learning Phase 1

ESG Perspective Exchange

Co-learning Phase 2

Learn from ESG benchmark companies

Co-learning Phase 3

Themed ESG Ecosystem Discussions

ESG Academy for Supply Chain Management Center

Since 2022, Winbond has been implementing 'ESG Intelligence Enhancement Education and Training,' initially aimed at its materials staff. Starting in 2024, staff involved in supply chain management, such as those from the materials department and outsourcing engineering department, have also been included in the ESG education and training programs. The training covers a wide range of topics, including sustainable cultural literacy, current climate change events, ESG fundamentals, carbon issues, and green energy development. In total, the training has provided 33 hours per person, amounting to 4,831 hours in total. Looking ahead, Winbond plans to introduce concepts of mandatory and elective courses and incorporate resources from academia and research institutions to assist staff in innovating within their existing roles and to continue advancing on the sustainability journey.

Professional Sustainability Courses

- Basic Concepts and Overview of ESG

- Analysis of Domestic and International Regulations and Trends

- Corporate Carbon Issues (Carbon Management, Carbon Reduction, Carbon Assets)

- Introduction to Innovative Energy (including Green Energy Certificates and Renewable Energy)

- Various Sustainability Management Standards

On-site training

- On-site Understanding of Supplier Sustainability Management Systems

- Understanding Supplier Product Processes and Lifecycle

- On-site Visits to Supplier Factory Operations

- Special Topic Seminars

Supplier Sustainability Training

Sustainable Supply Chain Upgrading+Forums

The purpose of conducting the Sustainable Supply Chain Upgrade+ Forum is to enhance suppliers' acquisition of sustainable professional knowledge and implementation motivations through professional courses and an open-discussion format. The forum also encourages suppliers to share knowledge with colleagues from different units within the company, leveraging learning leverage and information diffusion effects to gradually integrate sustainability DNA as a key factor in the operational considerations of each supplier.

Accumulated performance to 2024

Cumulative number of forums:5

Topics:Carbon footprint, water resources management, supply chain resilience, human rights due diligence management, The G Power in ESG: Accumulation of comprehensive ESG management of the supply chain

Number of suppliers affected:2,615人

Advanced OSAT Technique and Technology Forum

Innovation is also a key success factor for sustainable supply chains. Enhancing the R&D capabilities of outsourced packaging and testing factories is equivalent to enhancing Winbond's product competitiveness. The purpose of the "Advanced Packaging Technology" forum is to facilitate direct communication between various units within Winbond and the backend packaging and testing processes through two-way dialogue. This aims to stimulate research and development of products that better align with future lifestyle benefits.

Accumulated performance to 2024

Cumulative number of forums:4

Topics: Introduction to advanced packaging processes, Flash programming applications and appearance inspection solutions, 2.5D / 3D IC Packaging Technology Development、Advance Assembly Testing solution

Number of suppliers affected:771

OSAT Suppliers Communication and Management Conference

2024 Topic: Inspiring Sustainable Performance through Innovative Thinking

Producing competitive and high-quality products not only relies on the quality control of all Winbond colleagues, but also requires the cooperation of outsourced packaging and testing factories. Winbond Electronics has close interactions with outsourced packaging and testing factories. Senior managers from packaging and testing factories all attended Winbond Electronics' 2024 Outsourcer Conference, with an attendance rate of 100%.

100% Attendance by All Subcontractors

At the 2024 annual meeting, Winbond's General Manager began with an analysis of the semiconductor industry landscape to strengthen the cohesion and continuous close collaboration with contractors. Building on quality as a core competitive strength, department heads further shared their insights on digital transformation, renewable energy, and carbon reduction management measures. They also shared their recent experiences and practices in sustainable development with the packaging and testing contractors.

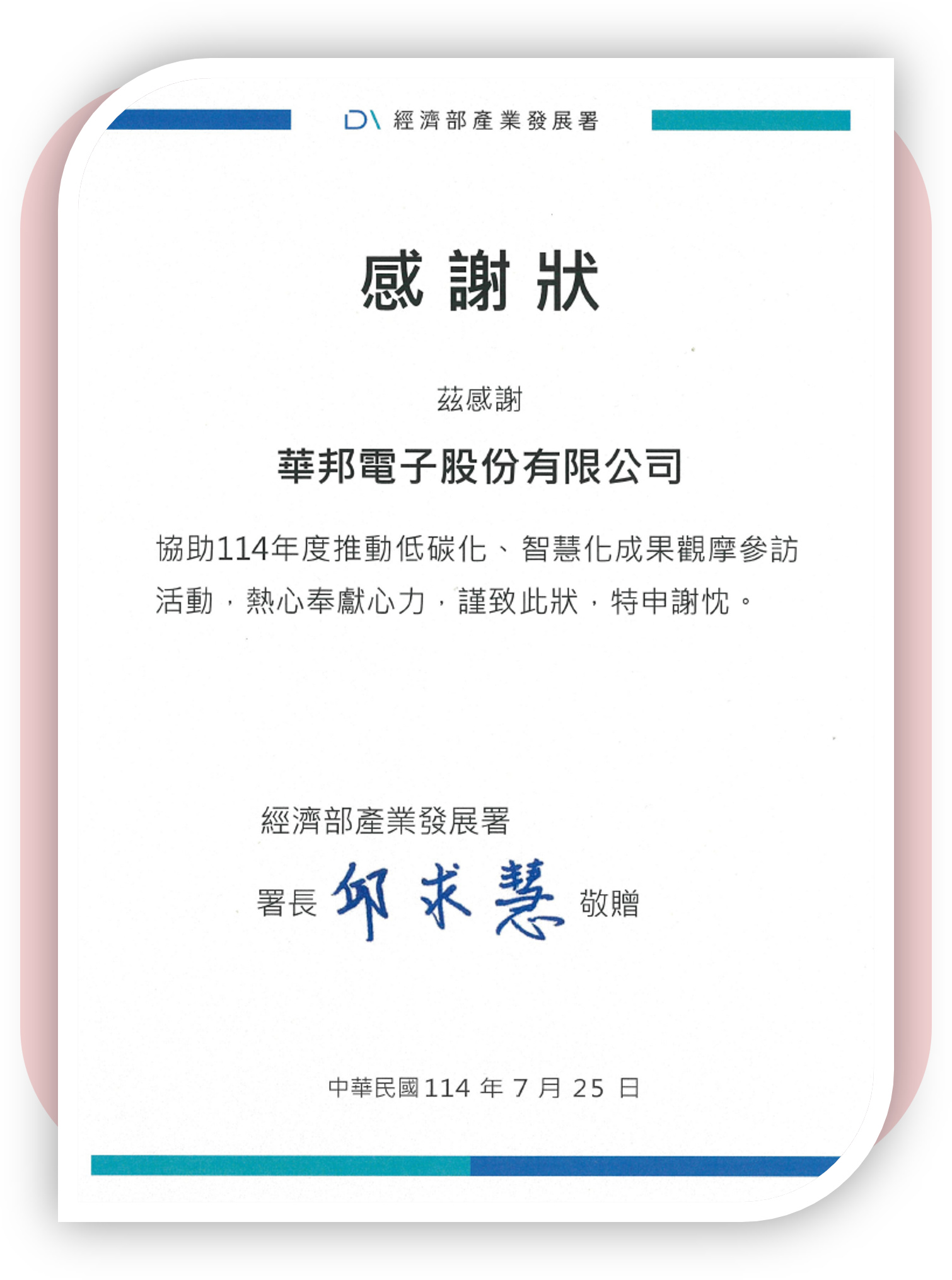

Commendation for Outstanding Sustainable Subcontractors

With the incorporation of ESG criteria into the regular evaluation of outsourcers in 2024, Winbond conducted a comprehensive assessment based on factors such as packaging technology research and development, quality, delivery schedule, cost, service, and sustainability performance. Outstanding outsourcer awards were given in recognition of the outsourcers’ continuous support and as an incentive for them to further enhance their green and low-carbon technologies.

- 2024 List of Award Winners

- Best Packaging Supplier – ChipMOS Technologies

- Best Test OSAT suppliers – PTI Technology

- Best quality – Winstek Semiconductor Co., Ltd.

- Best ESG Contribution – Walton Advanced Engineering, Inc.

Supplier ESG Strengthening Project

To firmly advance alongside with suppliers on the sustainable journey, in 2023, Winbond expanded its sustainable operations in the supply chain from an ecosystem perspective. In terms of the environment, cooperation focuses on low-carbon initiatives and joint beach cleanups; in terms of governance, Winbond invited suppliers to conduct procurement education and training together, thereby strengthening the sense of partnership between suppliers and Winbond. In terms of social inclusion, Winbond actively responds to the expectations of various stakeholders for sustainable supply chain management. Winbond firmly believes that in the face of a changing and challenging business environment, it is necessary to break away from linear thinking based on the supply chain, value chain, and industry chain, and to systematically reorganize and manage sustainability-related work with suppliers using a systemic approach in order to establish a sustainable growth mindset that embraces cooperation and mutual benefit in the long term.

Winbond Sustainability Supply Chain Low-Carbon Transformation Project

In 2023, Winbond collaborated with 13 companies including Powertech Technology Inc., Greatek Electronics Inc., Probe Test System Corp., Lingsen Precision Industries, Walton Advanced Engineering, Inc., DuPont Taiwan, Resonac Semiconductor Materials (Taiwan), Wonik Quartz Taiwan Co., LTD., United Industrial Gases Co., LTD., Hsing Mien Industry CO., LTD., Edwards Vacuum, Taiwan Puritic Corp., and Mega Union Technology Inc. to execute three major projects: “Reduction of Factory Process Gas Emissions,” “Implementation of Lean Electricity and Water Conservation Measures in Factories,” and “Promotion of Greenhouse Gas Inventory and Hotspot Analysis in the Supply Chain.” During the collaborative period of this project, a total investment of over 200 million New Taiwan Dollars was made. Within two years, these initiatives aimed at promoting low-carbon transformation gradually increased their carbon reduction capacity. It is anticipated that when the projects completed in 2025, an annual reduction of approximately 9,500 tCO2e will be achieved, equivalent to 14 times the annual carbon sequestration by the Daan Forest Park annually. This achievement not only serve as a model promoting the low-carbon transformation of the semiconductor industry supply chain but also showcases the multifaceted qualitative and quantitative operational methods with benefits, which make Winbond the first semiconductor to receive a full subsidy of NT$30 million. Therefore, the Ministry of Economic Affairs ‘ Industrial Development Administration invited Winbond to the “2023 Supply Chain Transformation and Innovation Forum" as a representative of the semiconductor industry to share its experiences in sustainable operations and low-carbon transformation.

-以大帶小.png)