Our Focuses|Sustainable Supply Chain|Conflict Minerals

Responsible Sourcing of Minerals

Winbond actively promotes the requirements of Responsible Business Alliances in the supply chain and considers them to be an essential element of supply chain management. In accordance with the management recommendations of the Organization for Eco-nomic Co-operation and Development (OECD) due diligence, Winbond first issued a statement on the non-use of conflict minerals. Secondly, the material analysis is carried out according to the composition of the company's products, and the suppliers that need to be investigated are identified to facilitate the implementation of due diligence. Suppliers are strictly required to select qualified smelters and update the information according to the validity period, and finally, based on the survey results, prepare a due diligence report on Winbond's conflict minerals every year for public notice.

Responsible Sourcing Management Process

-衝突礦產管理流程.png)

Winbond Conflict-free Minerals Statement

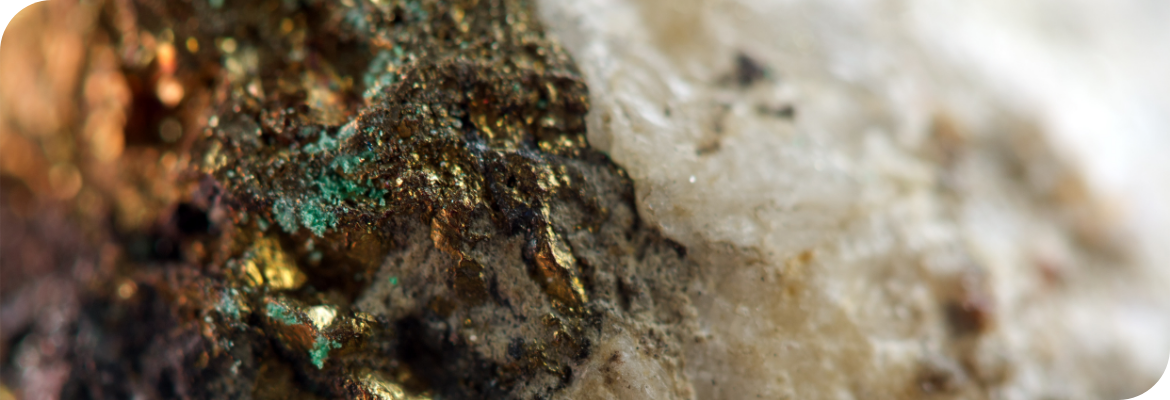

Winbond follows the RMI (Responsible Minerals Initiative) to conduct due diligence on the source and regulation of tantalum, tin, tungsten, gold, cobalt, and mica in the products it manufactures to ensure that its sourcing practices are in line with the OECD Guidelines for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas or an equivalent and recognized due diligence framework. At the same time, Winbond also requires all suppliers to comply with and sign the Code of Conduct and Ethics related to sustainable development, the Employee Code of Ethics, the International Declaration of Human Rights and the International Labor Organization's Tripartite Declaration of Principles, the adoption of green products, environmental protection and no hazardous substances (HSF) policies, or comply with the requirements set by the Responsible Business Alliance (RBA). In 2024, all qualified suppliers will sign the Winbond Code of Ethics and Integrity, the Winbond Supplier Code of Conduct Commitment (including the terms of the RBA and Conflict Minerals Statement) to ensure that there are no "responsible minerals from substandard smelters" and products from Congo or countries and regions adjacent to conflict zones, and comply with applicable regional and international laws on responsible minerals.

Identification and Results of 3TG Metal Sources

Winbond first determines the composition of the supplied products based on the Safety Data Sheet provided by the supplier and identifies whether it contains specific metals, and then adopts the Conflict Minerals Reporting Template (CMRT) and the Extended Minerals Reporting Template (EMRT) Investigate suppliers whose product composition involves gold (Au), tantalum (Ta), tin (Sn), tungsten (W), cobalt (Co), mica, and other responsible mineral sources as reported in the Responsible Minerals Initiative (RMI). In 2024, a total of 15 suppliers will be surveyed, and the smelters from which various metals come from 26 countries include North America, South America, Europe, Asia and Central Asia, and a total of 88 qualified smelters will provide metal smelting. In addition, Winbond has also formally implemented on-site audits of suppliers on conflict production, which not only strengthens Winbond's determination not to use conflict production, but also ensures suppliers' commitment to conflict production management through on-site audits. In 2024, a total of 2 Japanese raw material suppliers and a total of 15 written audits will be conducted on the spot, all of which will comply with the requirements and have not been prohibited from selling related products to Winbond.-各類金屬合格冶煉廠.png)

Since global political relations are not constant, and in recent years, cross-border government conflicts or wars have occurred only overnight, in order to ensure that Winbond abides by its commitment not to use conflict protonium, Winbond has taken three measures to prevent and control the risks in the use of 3TG metal. First, we will continue to issue regular due diligence and issue annual due diligence reports on conflict minerals, and simultaneously expand to suppliers who use 3TG metals, and conduct on-site audits to ensure that they are consistent with their words and deeds. Second, we will continue to trace the source of suppliers who have lawfully mined 3TG ore sources at home and abroad and have also implemented conflict production management policies, and implemented diversified supply risk control and conflict prevention of mine sources. Third, Winbond will do its best to assist the suppliers in the traceability of other compliant minerals for suppliers with potential use or procurement risks of conflict mineral production, and if there is no improvement, Winbond will completely stop trading with the supplier. It is worth mentioning that Winbond's supply chain team is also actively paying attention to the customer's requirements for conflict production management, and dynamically adjusting internal management measures on the basis of pre-prevention, hoping to ensure the humane spirit of mineral mining with the strictest standards on the one hand, and economic means to curb the mining of related minerals in armed areas on the other hand. In 2024, in accordance with the regulations of the RBA and the U.S. Securities and Exchange Commission, Winbond will also actively respond to the Dodd-Frank Act (DFA) and strengthen the implementation of corporate social responsibility. All product outer packaging will bear a "Conflict-Free" label, explicitly declaring that the company's products contain no conflict minerals.

Risk Level | Scenario | Management Action |

|---|---|---|

Level 0 | The supplier's products or raw materials do not contain any responsible minerals. | Winbond makes a declaration and requests the supplier to comply and sign accordingly. |

Level 1 | Minerals are sourced from qualified smelters recognized by RMI or other third-party verification bodies equivalent to OECD due diligence, and NOT from the Democratic Republic of the Congo or adjacent countries. | (1) Winbond makes a declaration and requests the supplier to comply and sign accordingly. |

(2) Request the supplier to verify and fill in the source of responsible minerals in order to understand the origin country. | ||

Level 2 | Minerals are sourced from qualified smelters recognized by RMI or other third-party verification bodies equivalent to OECD due diligence, and the origin is the Democratic Republic of the Congo or adjacent countries. | (1) Winbond makes a declaration and requests the supplier to comply and sign accordingly. |

(2) Request the supplier to verify and fill in the source of responsible minerals to understand the origin country, and request the supplier to propose a plan for changing the source of responsible minerals. | ||

Level 3 | Minerals are sourced from smelters NOT recognized by RMI or other third-party verification bodies equivalent to OECD due diligence. | (1) Require suppliers to obtain RMAP certification, and request non-certified suppliers to stop sourcing and seek compliant sources. |

(2) Require suppliers to propose improvement/replacement plans, declarations, and RMI reports. | ||

| Note: Winbond actively monitors stakeholder requirements regarding conflict minerals management, and dynamically adjusts internal supplier management measures based on a preventative approach. | ||

-風險控管三措施.png)